| English | 简体中文 | |||||||||

|

|||||||||

| Home | Product | Download | Support | Literature | Purchase | About Us | |||||||||

|

|

|||||||||

The structure resonance of a tensioner in firing engine plays a importance role in engine noise performance. During engine run-up testing, acceleration response on different positions of the tensioner are measured. By using ModalVIEW software and National Instruments DSA hardware as the modal testing and analysis tool, the mode shape of tensioner at strucutre resonance is obtained.

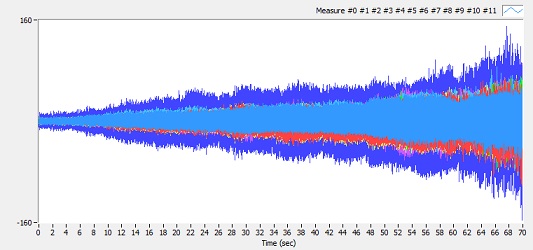

The rotating speed of the engine is changed from idle speed to 5500rpm in linearity. At the same time, vibration signals and tacho signal are measured simultaneously with sampling rate being 25kHz. The duration is about 70 second, as the following figure shows.

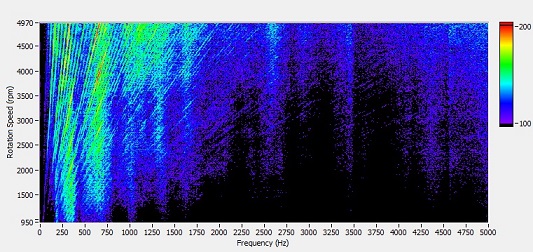

The order spectral map of vibration responses from firing engine is shown as the following figure, which indicate some structure resonance zones.

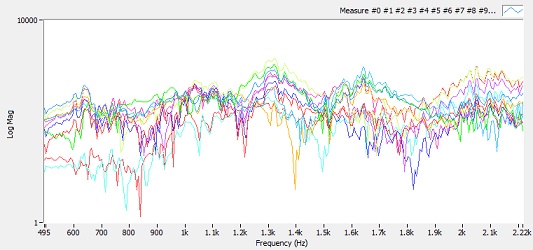

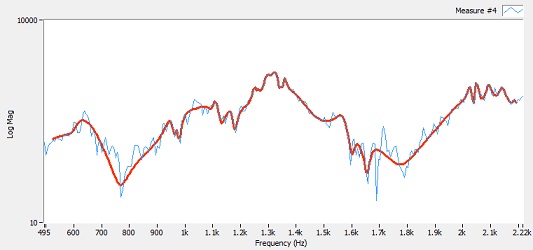

The order-tracked vibration signal is further converted into ODS FRF (modified cross-power spectrum) for modal parameter extraction, as the following figure shows.

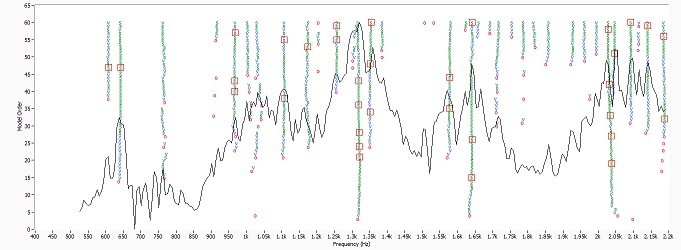

Gabor transform based order-tracking method and use the least squares complex frequency domain (LSCF) to process generated ODS FRF. Modal analysis for the structure is finished with ModalVIEW’s advanced mode estimation method based on mode stabilization diagram. The following figure shows the clear mode stabilization diagram from measured FRF data.

The synthesized ODS FRF data matches well with the measured FRF data

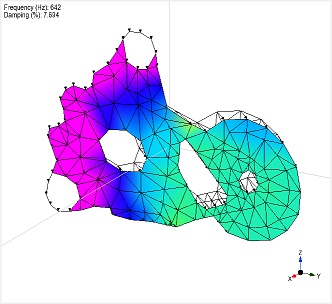

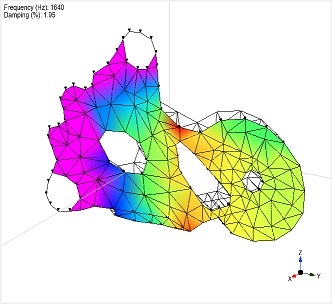

Some of the mode shapes are displayed as following :

Conclusion

Vibration excitation caused by engine crankshaft rotation can be viewed sweep excitation signal in a broadband frequency range. Correspondingly, the structural vibration response spectrum is also a broad band, which can be used for operational modal analysis for engine FEAD accessory, such as tensioner . The combination of Gabor transform based order-tracking method and the least squares complex frequency domain (LSCF) method is effective and powerful tool for operational modal analysis of engine FEAD accessories, which is useful for root cause analysis of engine noise.

![]() Download this application note in

PDF format

Download this application note in

PDF format